In the world of fashion, a coat is more than just a piece of clothing; it’s a statement, a shield from the elements, and a canvas for personal style. We understand that creating a quality coat is a meticulous process that requires attention to detail, craftsmanship, and a passion for excellence. We believe that the devil is in the details for coat making. Let’s explore the seven key concerns to creating a quality coat and highlight the importance of each in creating a masterpiece.

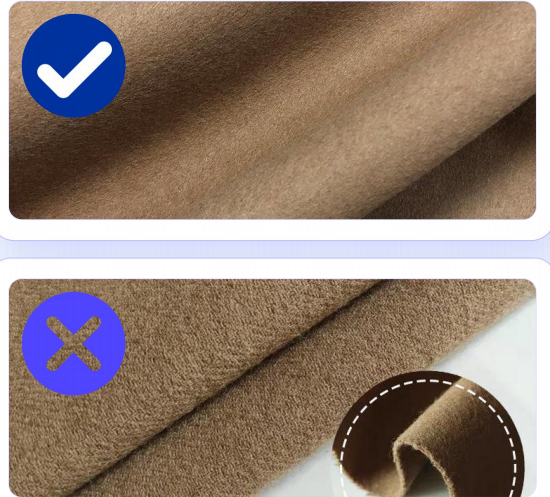

1. Fabric selection: the basis of quality

The journey begins with fabric selection, which is the foundation of any great outerwear. We prioritize premium fabrics such as merino wool, cashmere, alpaca and merino wool blends. Each fabric is meticulously tested for feel and weight, with a preference for fabrics weighing 800 g/m² or more. This ensures the outerwear not only feels luxurious, but also provides the necessary warmth and durability.

Fabric pre-treatment is also crucial. Depending on the intended function and aesthetic, some fabrics feature a jacquard weave or a water-repellent finish. This attention to detail ensures that the jacket meets specific functional requirements while maintaining its aesthetic. By choosing the right fabric, we lay the foundation for a jacket that exudes quality and sophistication.

2. Digitalized cutting

After selecting the fabric, the next concern is machine cutting. The pattern design is tailored according to the customer's size specifications and actual wearing needs. In this process, precision is crucial. We use advanced technologies such as laser cutting and digital cutting to meet cutting needs with high precision and efficiency.

The process is not only about aesthetics, but also about ensuring the jacket fits the wearer perfectly. A well-cut jacket not only enhances the silhouette, but also provides comfort, allowing the wearer to move freely while looking stylish.

3. Lining stitching: hidden comfort layer

The third concern is to sew the lining, which adds an invisible layer of comfort to the coat. The main lining is usually made of cupro or acetate, while the sleeve lining is made of polyester to reduce friction. The combination of the two structures is designed separately. This thoughtful design usually facilitates movement.

Details are crucial at this stage. For example, the underarm gussets are reinforced for extra support, while the hem lining is hand-sewn to prevent curling. These meticulous touches ensure that the coat not only looks great, but feels great too.

4. Lining fabric shaping: creating a straight silhouette

The fourth concern, shaping the lining, demonstrates the exquisite skills of traditional craftsmanship. Each coat is lined by hand. This time-consuming and laborious process is essential to shaping the natural chest and waist curves, ultimately creating a pleasing silhouette.

The shaping of the lining fabric is a testament to the skill and dedication of our artisans. We invest time and effort to ensure the coat drapes beautifully, enhancing the wearer's overall look.

5. Hand quilting: millimeter-level precision

The fifth concern is hand-quilting with millimeter precision. At this stage, the fabric stretching process involves steaming the collar fabric to shrink it by 1-2 cm, thus creating a three-dimensional curvature. This attention to detail not only enhances the beauty of the jacket, but also ensures that the collar fits perfectly to the wearer's neck.

Blind stitching is another key aspect of this craft. It allows the seams to be visible yet imperceptible from the outside, while maintaining the integrity of the coat’s design. This exquisite craftsmanship is what separates a quality coat from an ordinary one.

6. Carefully crafted: balance between functionality and aesthetics

The sixth concern is to carve in detail, striving to balance practicality and beauty. This process includes the processing of button holes and the processing of edges. Every detail is carefully carved to enhance the overall design of the coat. The design of button holes is not only practical, but also complements the style of the coat, adding a touch of exquisite style.

The edges are carefully polished to ensure the coat retains its shape over time and has a natural structure. We paid attention to these details to create a coat that is not only beautiful but also practical for everyday wear.

7. Six quality checks: ensuring excellence

The birth of a high-quality coat ultimately requires six quality inspections. We adhere to the uncompromising quality assurance concept. Before each coat is delivered to the customer, it will undergo multiple quality inspections in multiple dimensions to ensure that it meets our high standards.

These inspections cover everything from fabric integrity to sewing precision, ensuring that every coat truly reflects our commitment to quality. By implementing stringent quality control measures, we ensure that our customers receive a product that exceeds their expectations.

Conclusion: The Art of Craft

Creating a high-quality outerwear requires meticulous attention to every detail. From fabric selection to quality inspection, every process is critical to creating a garment that combines quality, style and function. We are more than just a supplier; we want to be a strategic partner committed to providing excellent products that match your brand image.

We are constantly innovating, striving for excellence, and always dedicating ourselves to the art of craftsmanship. We know that in the world of fashion, details make the difference. We focus on these details to ensure that every coat we create is not just a piece of clothing, but a work of art that our customers will treasure for years to come.

Post time: May-20-2025