In the world of fashion, the allure of a beautifully tailored woolen coat is unquestionable. More than just a piece of clothing, it is a testament to the artistry and craftsmanship that went into its creation. Behind the visible elegance lies a world of intricate detail, with every stitch crucial to the woolen coat’s personality. This article takes a closer look at the hidden elements that influence the overall quality and sophistication of a woolen coat, focusing on key processes such as fusible interlining, blind stitching, lining sewing, as well as ironing and shaping.

1.The Importance of Fusible Interlining in Wool Outerwear Construction

Often referred to as the "invisible skeleton" of a woolen coat, fusible interlining plays a vital role in determining the overall quality and performance of a jacket. Fusible interlining is a special material that is cleverly embedded between the outer fabric and the lining, significantly affecting the three-dimensional feel, wrinkle resistance and elasticity of a woolen coat. Understanding the importance of this part can help consumers make an informed choice when selecting a high-quality woolen coat.

One of the main functions of a fusible interlining is to enhance the fit of a jacket. This refers to the ability of a coat to retain its shape and structure, creating a custom feel that hugs the contours of the wearer. High-quality fusible interlining helps to enhance the structural integrity of a jacket, allowing it to drape elegantly while retaining its shape. A jacket made with quality fusible interlining will have a natural, three-dimensional appearance that enhances its overall aesthetic.

In today's fast-paced world, wrinkle resistance is a highly sought-after attribute in outerwear. Fusible interlining plays a key role in achieving this attribute. A well-constructed jacket with a quality fusible interlining will effectively prevent wrinkles, keeping the wearer looking fresh and looking great all day long. To assess the quality of a fusible interlining, you can perform a simple test: gently squeeze the front of the jacket. If the fabric naturally rebounds, the fusible interlining is of good quality. On the other hand, if the fabric still wrinkles, or bubbles appear due to aging of the glue, the fusible interlining is of poor quality and may affect the life and appearance of the outerwear.

Elasticity is another key factor that fusible interlinings influence. This property refers to the ability of a material to return to its original shape after being stressed or deformed. Jackets with elastic fusible interlinings are able to withstand the rigors of daily wear and retain their structure and appearance over time. This is particularly important for jackets that are often exposed to the elements. High-quality fusible interlinings ensure that the jacket retains its shape under movement and stress, providing both comfort and style.

There are several factors to consider when evaluating the quality of a fusible interlining. The first is the feel of the fabric. A high-quality fusible interlining is both soft and strong, which contributes to the overall comfort of the outerwear. The weight of the fusible interlining can also reflect its quality; heavier fusible interlinings generally provide better structure and support.

Another key factor is the adhesion of the interlining to the outer fabric. A well-bonded interlining will not peel or bubble, ensuring a seamless connection to the outer fabric. This is essential to maintaining the beauty and functionality of the woolen coat.

2.Hidden Line Technique: Invisible Exquisiteness

The artistry of the coat goes far beyond its appearance; hidden seams ensure the outerwear’s integrity and elegance. The fluidity of the coat’s silhouette depends largely on the quality of the seams within. Techniques such as blind stitching are used to hand-sew hems, lapels and other parts, ensuring that no traces of seams are visible from the outside while maintaining a soft and smooth touch.

Another hallmark of high-end coats is the use of bias-cut strips or ribbons to sew inseam. This attention to detail prevents fraying at the edges and prolongs the life of the jacket. The neat alignment of checks and stripes is another sign of craftsmanship. High-quality coats require an extra 20%-30% of fabric to ensure that the pattern lines up perfectly at the seams, and this craftsmanship is something luxury brands are proud of.

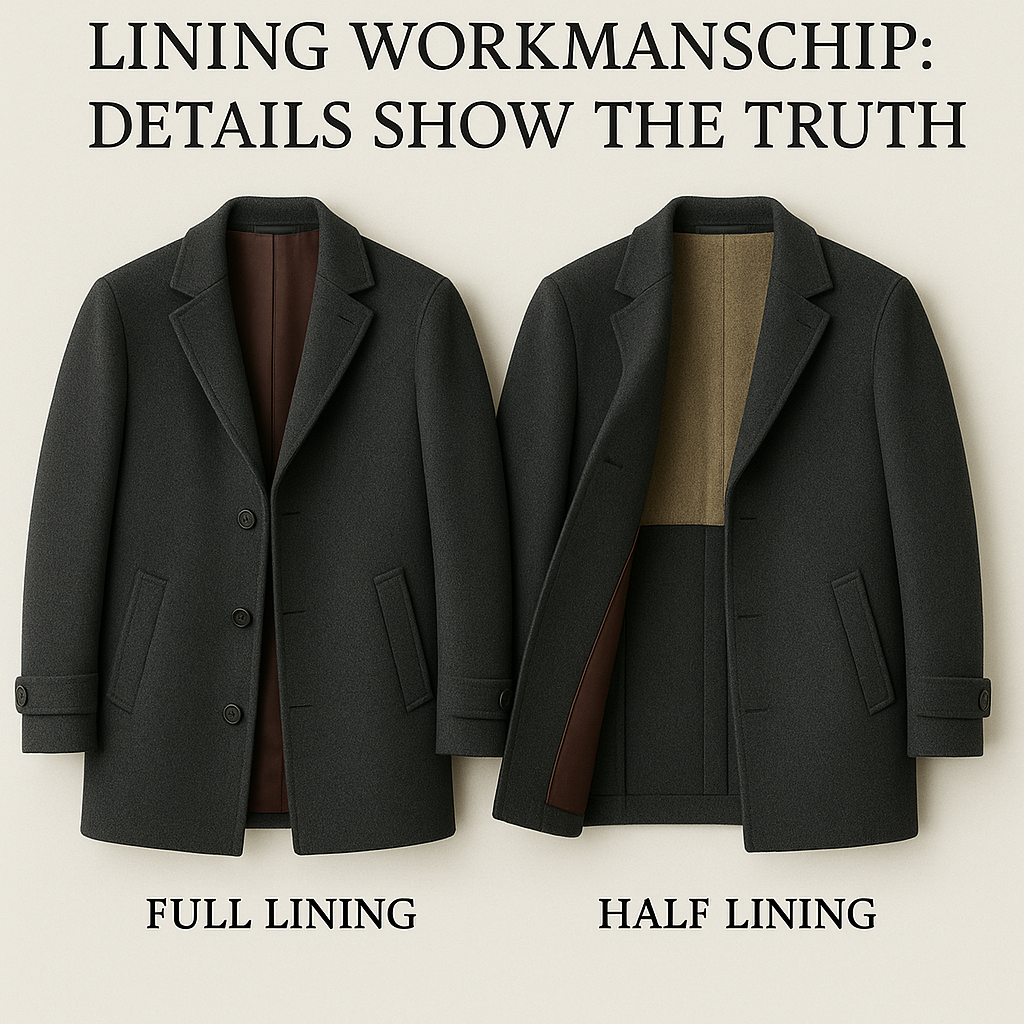

3.Lining workmanship: details show the truth

The lining of a jacket is not only a functional element, but also a key factor affecting the comfort and flexibility of the overall design. The craftsmanship of the lining can significantly improve the wearing experience. There are two main types of lining: full lining and half lining.

Full lining is a great feature of high-end outerwear, as it completely covers the internal seams, preventing any irritation to the skin. This pursuit of comfort is essential to creating a sense of luxury. On the other hand, in order to save weight, half lining is often used, leaving specific areas such as the back unlined. While half lining can be a practical choice, it must be weighed against comfort and durability.

The choice of lining material is also crucial to the overall quality of a woolen coat. High-end woolen coats are often lined with silk or high-quality cupro, which not only enhances the comfort level but also the aesthetics of the garment. The delicate balance between the outer fabric and the lining can make a woolen coat go from ordinary to extraordinary.

4.Ironing and shaping: giving woolen coats "vitality"

Ironing and shaping are often underestimated in the process of making a woolen coat, but they are essential to achieving a refined look. Ironing not only removes wrinkles, but is also a key step in giving a woolen coat its "life". Natural fabrics such as wool and cashmere require careful care and often require steam ironing to relax the fibers. This process allows the fabric to reshape, ensuring it retains its shape even when worn for a long time.

The shrinking process is another critical step in shaping a woolen coat. By applying localized heat, tailors can stretch or shrink the fabric to perfectly fit the body. This level of customization is the hallmark of high-end tailoring, where the goal is to create a outerwear that feels as if it was tailor-made for the wearer.

Conclusion: The Art of Craft

All in all, the craftsmanship behind a woolen coat is a symphony of techniques and materials that come together to create a masterpiece. From the fusible interlining that supports the structure to the invisible seams that ensure an elegant texture, every detail is crucial. The exquisite craftsmanship of the lining, as well as the ironing and shaping processes, further enhance the quality, comfort and durability of the woolen coat.

As consumers, understanding these elements enables us to appreciate the artistry that goes into outerwear production. This allows us to make informed choices when selecting woolen coats, ensuring that the jackets we purchase not only look beautiful, but also reflect the craftsmanship of the piece. The next time you put on a beautifully tailored woolen coat, take a moment to admire the invisible lines that hold it together because every step is made with great craftsmanship.

Post time: May-22-2025